by M. Fujita, Chemist and Maltster for the Sapporo Brewing Company, of Sapporo, Japan

As published in The American Brewers’ Review – 1902

Western people are in the habit of saying that we of the East begin everything at the wrong end. For instance, if you ask me: “Don’t you like this beer?”, I would answer “Yes, I don’t like it,” where you would say, “No, I don’t like it.” And yet, my answer would be quite as logical as yours, if not more so. Perhaps, it is not so much that we do things wrong, as that we do them differently from you.

Thus, your common beer, which is used on ordinary occasions, is keg beer, and if you drink beer at banquets or dinners, you drink bottle beer. In Japan, we reverse this practice. Keg beer is used at dinners and banquets, whereas he common form in which it is used is bottle beer. The output of the Sapporo Brewing Company consists almost entirely of bottle beer, only 5% of it being keg beer. I should add, however, that of late years some public beer gardens after the German pattern have established in the larger cities, and here, of course, keg beer is the rule.

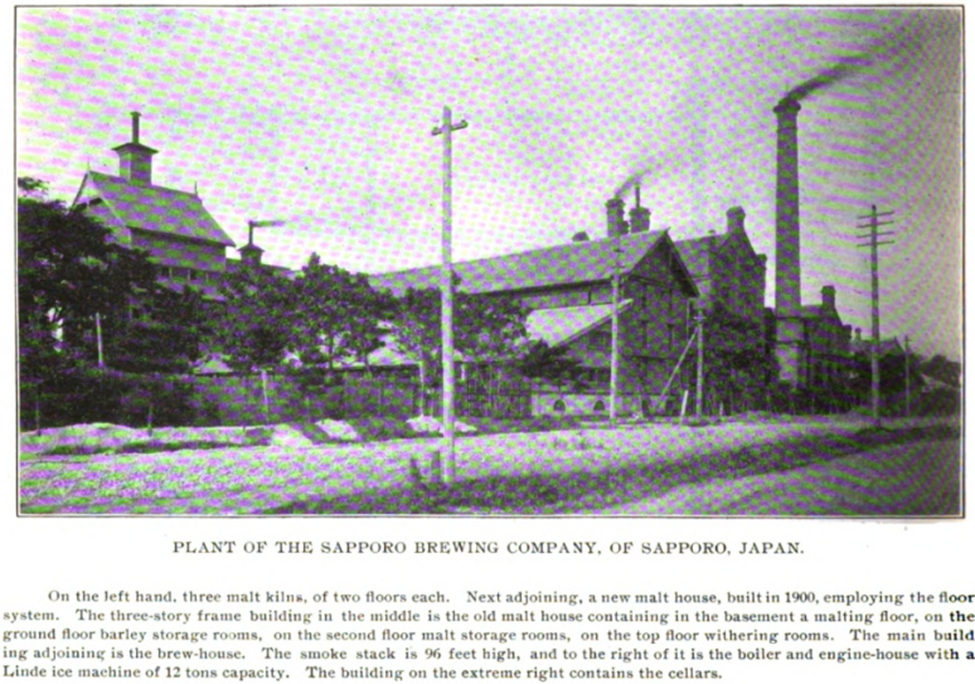

Another thing that we did which may seem wrong to you and perhaps is only different from the way you do, is the location of the brewery at Sapporo, which is situated I the central part of the Island of Hokkaido, lying to the north of the main island of Nippon, which is Japan proper. Hokkaido is not very densely populated, nor is the population much given to the use of beer. There are only two places of any consequence at all in the island of Hokkaido, namely, Ottaru and Hakodate, which, besides Sapporo itself, consume any noteworthy part of the beer produced by our brewery. By far the greater part of our output, which amounts to 35,000 hectoliters a year, goes to Tokio and other cities on the main island. And it was well known when the brewery was founded, that this would be the case. And yet the brewery was started by the government in 1876. The object of the government was rather to create a local market for the barley which was raised in considerable quantities in that neighborhood. According to Western ideals this was perhaps putting the cart before the horse. But, in a country like ours, where the initiative for commercial enterprise emanates largely from the government instead of from individuals, this policy was, without a doubt, proper, and the results have demonstrated its wisdom. In 1886, a purchaser was found for this government enterprise which, at that time, had an annual output of only 2,500 barrels, the purchaser being the firm of Okura & Co. Two years later, a corporation was formed by the name of the Sapporo Brewing Company, which now controls the business and has built it up to its present respectable dimensions. In the meantime, the consumption of beer has been increasing greatly in the Flowery Kingdom, and the Company is now building a new brewery in the city of Tokio. This brewery is to have an initial capacity of 35,000 barrels but is so designed that it can be readily increased to a capacity of 60,000 barrels. The capital stock of the Sapporo Brewing Company at present amounts to $300,000, roughly speaking, and additional means were raised by issuing debenture bonds.

The Sapporo Brewing Company is the only one in Japan that makes all its own malt, all other breweries importing most of the malt they use from abroad, mostly from Germany. The only adjunct used is rice, which is mixed with the malt to the amount of about 15 per cent.

Western people are fond of calling us imitators of their achievements. It should be borne in mind, however, that if we were thoughtless imitators, we should not accomplish a great deal, in view of the fact that our environment differs very materially from those with which Western nations have to deal. For instance, if we would simply imitate, we should, no doubt, adopt the gravity principle of brewery construction which has been so successfully carried out in the United States. However, in the construction of the new brewery at Tokio, this principle was only partly adopted, for the reason that in our country it is unsafe to build structures of great height, owing to the frequency and violence of the earthquakes that visit our country. We were obliged, therefore, while recognizing he manifest economy of this construction, to modify it so as to suit the physical condition of our environments.

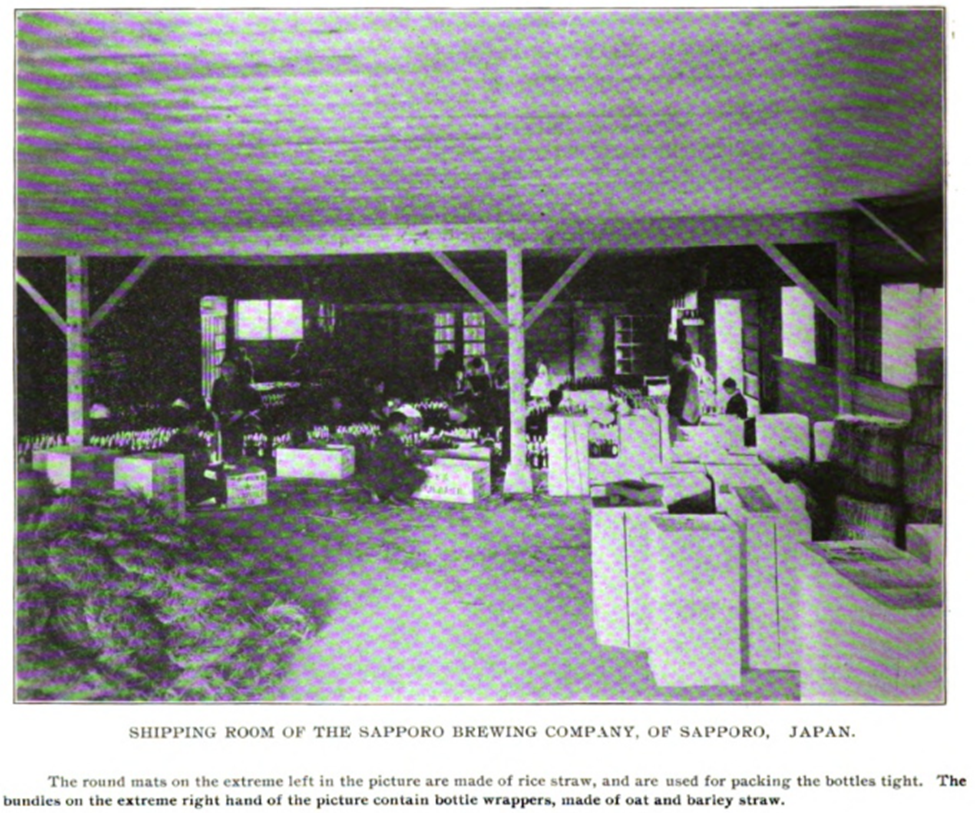

The bottle shop of our brewery would present a very peculiar spectacle to a brewer from the Western countries. A glance at the illustrations of that accompany this article will show that we do not employ machinery to a great extent. The reason is simply that labor is very cheap in our country and we employ about 100 men, women, and children in our bottling and shipping rooms more economically than we could the machinery which would be necessary to put out the amount of bottled beer that we produce. The consumption of beer is quite insignificant in the winter, so the work of bottling and shipping is crowded into a comparatively short time. Still, we manage to keep our help busy during the winter by employing them in our maltings.

Our bottling house, which adjoins the cellar, covers an area of 8,000 square feet, and is divided into three parts, which were built at different times. In one part we do the filling, corking and washing; in another, the steaming; in a third, the packing and shipping. The beer is carried from the cellar in a two-inch pipe. The filling and corking is done by men; the washing, by women and girls, who also do the labeling. The packing again is done by men.

The bottles are attractive looking, reddish-brown affairs, capped with tin-foil and handsomely labeled. When exporting to the island of Formosa the bottles are wired by hand. Wrappers made of straw are used to protect the bottles. The corks are mostly imported from Germany. The boxes are similar to those used in the United States. About 20 per cent of the bottles consist of pints the rest quarts, and four dozen are placed in a box. “The brewery makes its own bottles, having a glass factory for that purpose. It also makes its own kegs which are half, quarter, and eighth hectoliters. The bottling machinery was supplied by the firm of Heinrich Gerke, of Berlin, Germany. There is a soaking tank in which the bottles lie for ten to twelve hours, then there is a bottle washing machine, also two eight spout fillers which will fill about 130 barrels a day. There is a steaming tank supplied by the Maschinenfabrik Germania, of Chemnitz, Germany. In the cellar is an Enzinger filter, a Deckebach cooler and a pressure regulator, besides other machinery.

Up to the present time, beer continues to be a luxury. The retail price is 30 sen a quart, which is equal to 15 cents American money, but when the purchasing power of money is considered, answers about to 25 cents in the United States. In 1900, Japan had eleven breweries producing 200,000 hectoliters a year. In 1901, a decrease of over 10 per cent took place owing to the imposition of a tax equal to about $3.50 for two hectoliters. The most popular brand is of the Kulmbacher type, or Sapporo “karo” (black) beer.

The present officers and directors of the Sapporo Brewing Company are:

President, Y. Shibusawa

Manager, C. Uyemura

Directors, K. Okura and S. Asano

Brewmaster, K. Yagi